Seicenc is a company specializing in precision CNC machining services. After receiving the customer’s drawing, the general factory will analyze the drawing to determine the processing technology, such as the CNC lathe, machining center, turning and milling compound machining center, etc. The programmer needs to analyze the drawing before performing an actual operation and product inspection. So, how to analyze the processing technology of drawings?

1. Dimensioning method of CNC machined parts drawings

The dimensions on the drawings are an important basis for manufacturing and inspecting parts. During production, the dimensions on drawings cannot have any errors. In addition to being correct, complete and clear, marking dimensions on drawings should also consider reasonable requirements, not only to meet design requirements, but also to facilitate processing and measurement. Dimensions mainly include functional dimensions, non-functional dimensions, nominal dimensions, basic dimensions, reference dimensions, repeated dimensions, etc. The dimensions marked on the drawing are complete and correct, which is convenient for the processing personnel to analyze, process and measure, and determine the selected blank size and material number according to the dimensional accuracy.

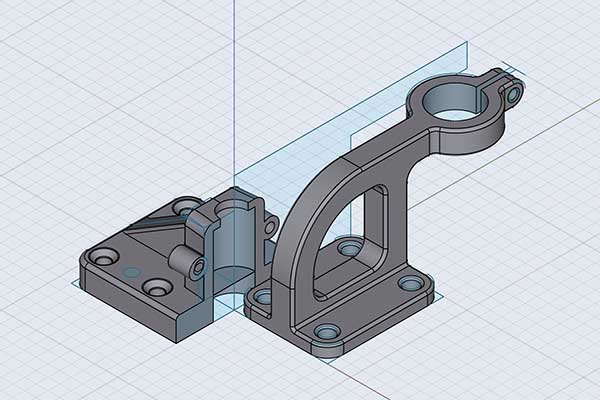

2. Analysis of geometric elements of CNC machined parts contour

The contour of the part is mainly composed of the cylindrical surface, spherical surface, groove, keyway, inner hole and so on.

3. Process analysis of CNC machined parts structure

General CNC lathes cannot be used. If it is too long, it is easy to have the problem of tool vibration or low surface roughness. Therefore, during processing, auxiliary tool holders and auxiliary fixtures must be provided. Seicenc has specialized CNC lathes. Also pay attention to heat treatment, because it will be deformed, bent or S-shaped after hardening.

4. Analysis of CNC machining parts precision and process requirements

① Part precision and technical requirements are complete and reasonable.

② During the machining process, CNC machining precision is required to be high, and the machining process is divided into rough machining, semi-finishing machining and finishing machining.

③ Whether the outer circle size requires high position accuracy. All the processes in this section except the keyway should be completed in one clamping process.

④ Workpieces with high surface roughness requirements should be cut at a constant peripheral speed.

It is our process analysis method for CNC machining drawings. Of course, the drawing requirements of different industries are also different. For example, in the medical industry, medical equipment has high requirements for components. This is why medical device manufacturers are accountable to end users. They place high demands on the quality and precision of their products. If you have precision CNC processing needs, please contact us, and we will serve you wholeheartedly.

Let Seicenc boost your business today!

Seicenc has been in CNC machining industry for 12 years, let us provide you with high quality custom precision machined parts.

By the end of 2022, we have worked with more than 1,000 clients in more than 30 countries, and supplied them over 1 million unique parts.

Do not hesitate. Just contact us right now! We will give you an instant quotaion within one days!