Material Comparison Guide of CNC Machining

Choose from hundreds of CNC manufacturing materials including various grades of metals and plastics. Each material has its own set of challenges and requires specific tooling, speeds and feeds. When selecting a material, we should consider the material properties, manufacturability characteristics, appearance and cost. For milling and turning dimensions by material, we can check maximum part extents for machining.

Metals:

| Material | Image | Description | Feature | Application | Finish |

|---|---|---|---|---|---|

| Aluminum |  | Aluminum is a versatile material with properties that make it ideal for CNC machining. Aluminum has excellent machinability, welding and electroplating properties as well as good corrosion resistance. The metal is also characterized by a high strength-to-weight ratio and good temperature resistance. After machining, aluminum has a low risk of deformation or defects and is easy to polish and color. | High strength-to-weight ratio | Light & economic, used from prototyping to production | Anodizing, Media Blasting, Nickel Plating, Powder Coating, Tumble Polishing |

| Stainless Steel |  | Stainless steel is the low carbon steel that offers many properties that are sought after for industrial applications. Stainless steel typically contains a minimum of 10% chromium by weight | Good corrosion resistance + High Hardness | Industrial applications, fittings, fasteners, cookware, medical devices | Black Oxide, Electropolishing, ENP, Media Blasting, Nickel Plating, Passivation, Powder Coating, Tumble Polishing, Zinc Plating |

| Alloy Steel |  | The alloy steel made up primarily of iron and carbon, steel is known for its high tensile strength and low costs. The combination of these characteristics has made it a ubiquitous material in the construction, infrastructure, automotive, maritime, tooling, manufacturing and defense industries, among others. | Good machinability + Excellent electrical conductivity | Fixtures and mounting plates; draft shafts, axles, torsion bars | Black Oxide, Electropolishing, Media Blasting, Nickel Plating, Powder Coating, Tumble Polishing, Zinc Plating |

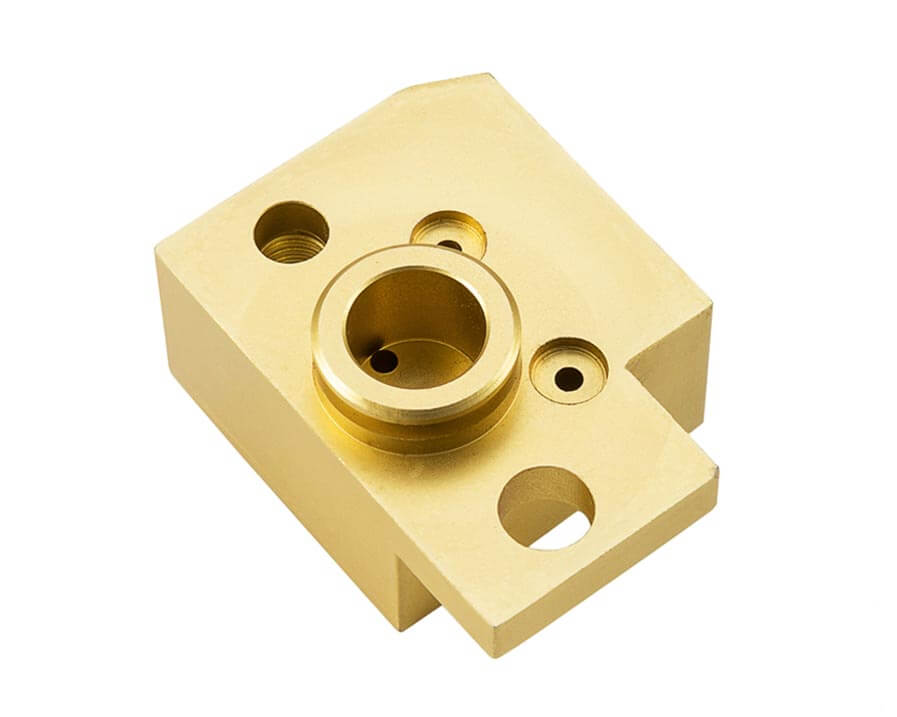

| Brass |  | Brass is a metal alloy made of a combination of copper and zinc. It demonstrates excellent electrical conductivity and good machinability. Known for its low friction properties and gold-like appearance, brass is commonly used in the architecture sector as well as to manufacture gears, locks, pipe fittings, musical instruments and more. | Good machinability + Excellent electrical conductivity | Gears, lock components, pipe fittings, and ornamental applications | Media blasting |

| Copper |  | Copper is a highly machinable metal employed in different capabilities based on its mechanical properties. It has good strength, hardness, superior thermal and heat conductivity, and corrosion resistance. Consequently, it is a popular material valued for its functional and aesthetic functions. Copper can also be made into alloys to improve its mechanical properties. | >99.3% Purity + Superior electrical conductivity | Bus bars, gaskets, wire connectors, and other electrical applications | Available as-machined, media blasted, or hand-polished |

| Titanium |  | Titanium has a number of material properties that make it the ideal metal for demanding applications. These properties include excellent resistance to corrosion, chemicals and extreme temperatures. The metal also has an excellent strength-to-weight ratio. | Corrosion resistance + High tensile strength | Aerospace fasteners, engine components, aircraft components, marine applications | Media Blasting, Tumbling, Passivation |

Plastics:

| Material | Image | Description | Feature | Application | Color |

|---|---|---|---|---|---|

| ABS |  | ABS is a commonly used thermoplastic polymer with excellent impact, temperature and chemical resistance. It is also easy to machine and process and has a smooth surface finish. ABS can undergo various post-processing treatments, including coloring, surface metallization, welding, electroplating, bonding, hot pressing and more. | High stability + Easy to process | Impact-resistant applications, production-like parts (pre-injection molding) | Natural, Black and other custom colors |

| POM (Delrin) |  | POM (Polyoxymethylene), also known as Delrin and Acetal, is an engineering thermoplastic characterized by its high stiffness, good machinability, excellent rigidity, low friction, high accuracy, and high dimensional stability, as well as chemical and abrasion resistance, these properties make it a great material in plastic CNC machining. POM materials are often used to make precision parts for a wide variety of applications. | Low-friction + High-stiffness | Mechanical gears, guiding elements, connector components like nuts and screws, and various custom parts | Natural, Black and other custom colors |

| PC (Polycarbonate) |  | PC (Polycarbonate) is a type of amorphous thermoplastic known for its high impact resistance and transparency. It also demonstrates good electrical insulation properties and moderate chemical resistance. | High impact resistance + High transparency | Light pipes, transparent parts, heat-resistant applications | Clear, Black |

| PA (Nylon) |  | Brass is a metal alloy made of a combination of copper and zinc. It demonstrates excellent electrical conductivity and good machinability. Known for its low friction properties and gold-like appearance, brass is commonly used in the architecture sector as well as to manufacture gears, locks, pipe fittings, musical instruments and more. | Good machinability + Excellent electrical conductivity | Gears, lock components, pipe fittings, and ornamental applications | White, Black and other custom colors |

| PMMA (Acrylic) |  | PMMA, also known as acrylic, is a transparent thermoplastic. One of the most widely used plastics in the world, PMMA demonstrates good chemical stability, mechanical properties and weather resistance. The material is also easy to process and to dye. | High transparency + Good chemical stability | Tanks, panels, and optical applications | Optically clear, opaque |

| PEEK |  | PEEK is a high-temperature resin used in safety-critical industries such as medical, aerospace and automotive. The high-performance material offers good chemical and heat resistance, as well as flame retardancy, and provides excellent strength and dimensional stability. | High-performance thermoplastic, very high strength, thermal and chemical resistant | Metal-alternative for high-stress applications | Opaque beige |

| PP (Polypropylene) |  | PP (Polypropylene) is an inexpensive thermoplastic with variable impact resistance depending on the grade. PP is wear-resistant, flexible and can have high elongation, while it also has high chemical resistance. | Excellent chemical resistance. Food-safe grades available | Containers, laboratory equipment | White |

| PE (Polyethylene) |  | PE (Polyethylene) is a thermoplastic available as high-density polyethylene or low-density polyethylene. High-density polyethylene, referred to as HDPE, is mainly used in blow molding and has high temperature resistance, oil resistance, steam permeability and environmental stress cracking resistance. PE also offers good electrical insulation, impact resistance and temperature resistance. | Excellent strength-to-weight ratio, impact and weather resistant | Piping, Packaging | White, Black |

| PTFE (Teflon) |  | PTFE (Polytetrafluoroethylene) is a versatile engineering plastic and synthetic fluoropolymer of tetrafluoroethylene with outstanding performance and properties. Teflon is a brand name of PTFE material. Polytetrafluoroethylene is a fluorocarbon solid, which is a polymer compound composed of carbon and fluorine. PTFE is hydrophobic, and neither water nor aqueous substances will wet it. | High and low temperature resistance, corrosion resistance, high lubrication and non-adhesion | Industrial components including gears, valves, bushes, manifolds, insulators, and fittings | White and other custom colors |

Let Seicenc boost your business today!

Seicenc has been in CNC machining industry for 12 years, let us provide you with high quality custom precision machined parts.

By the end of 2022, we have worked with more than 1,000 clients in more than 30 countries, and supplied them over 1 million unique parts.

Do not hesitate. Just contact us right now! We will give you an instant quotaion within one days!