CNC precision machining brings many benefits to almost all industries. Even revolutionized the way they approach their respective fields. One of the most important industries that benefit from precision machining is the medical industry. Many of the medical products we use today would not be possible without precision machining. Here, we examine how precision machining impacts the current and future state of medical advancement.

Machining to the Tightest Tolerances

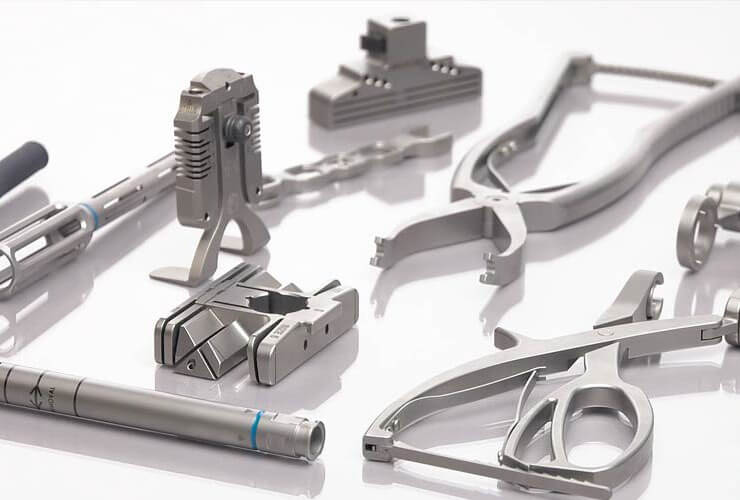

Safety, veracity and accuracy are the most needed in the medical industry. Precision machining helps create precise dimensions for surgical tools that fit the surgeon’s hand, resulting in more accurate results.

Machining is also used to create complex parts for lasers or robots that are used to enable operations that were impossible just a few years ago. Machining will help create more discoveries and innovations that advance medicine. These tools require very small and precise parts and tips to achieve functional parts that can only be created by CNC and EDM machining tools.

Because these tools are used in the most delicate surgeries (even vascular or brain procedures), even the smallest deviation can lead to disastrous results. This is where precision machining can be used. It helps to create tools that are not only precise, precise and precise for safety and reliability.

Wide Selection of Complex Materials

Materials used in a wide range of healthcare facilities need to meet requirements for durability, safety, non-reactivity to the human body, and ability to be sterilized. For example, joint replacement parts are often made of medical grade stainless steel or titanium for unrivaled strength, elasticity and function.

Precision machining enables these materials to be formed into complex shapes and sizes for specific medical applications. Some of these components are already embedded in patients, so they need to meet tight tolerances and have very smooth surfaces to eliminate burrs or streaks.

CNC and EDM precision machining are perfect for making these precision parts. Even the toughest materials can be used and turned into smooth parts. This machining method ensures that all parts are identical and assembled in the correct way for optimum performance.

Small For Comfort and Safety

Why do some medical tools or materials need to be miniaturized? Because only then can they provide comfort and security. Take insulin pumps, heart monitors, and defibrillators, for example. Thanks to precision machining, these designs are now miniaturized with smaller, more precise components. These implants can now be inserted into the body, allowing these people to lead relatively normal lives, enjoying freedom and freedom of movement.

Only through precision machining can these medical tools be precisely designed and manufactured. Once the design is under computer control, parts are immediately processed for smaller or larger operations. In summary, the contribution of this technology to the medical industry is beyond doubt.

Customized Equipment

Precision machining also allows for the custom design of certain medical devices for a more precise and individual fit. This is especially important for artificial devices (e.g. artificial knees, prosthetics) that need to accurately adapt and meet people’s needs. Precision machining is unique in that it can meet this need. With CNC machining, custom parts are simple and cost-effective. By entering designs into computer control, parts can be machined quickly and accurately. Precision machining drives the development of the medical industry and is an integral part in the long run.

Trends and Challenges

The accelerated development of the global market will inevitably link its upstream and downstream industrial chains, bringing massive demand for medical device processing and bringing a new wave of development to the precision parts manufacturing market.

Medical equipment is known for its complex structure, high precision and reliability requirements. The higher requirements for workpiece materials, processing accuracy and surface finish of medical device parts also mean that precision processing capabilities need to be improved. Precision machining technology is an advanced manufacturing technology developed to adapt to modern high-tech. In recent years, with the continuous deepening of China’s intelligent manufacturing, precision processing technology has made more and more contributions to the medical device industry.

With the development of the medical device industry, there are more and more types of medical devices, the structure is more and more complex, and the precision requirements are getting higher and higher. In order to meet the multi-variety and high-precision requirements of medical devices, high-speed, high-precision, intelligent, composite, and environmentally friendly precision machining has gradually become the main development direction of medical device CNC machining. In other words, there are high requirements for machine tools, fixtures, cutting tools, CAM software, testing equipment, and engineering capabilities. The demand of medical device manufacturers for high-quality parts processing suppliers has undoubtedly promoted the progress of processing technology.

Let Seicenc boost your business today!

Seicenc has been in CNC machining industry for 12 years, let us provide you with high quality custom precision machined parts.

By the end of 2022, we have worked with more than 1,000 clients in more than 30 countries, and supplied them over 1 million unique parts.

Do not hesitate. Just contact us right now! We will give you an instant quotaion within one days!