Available Surface Finishes of CNC Machining

Surface finishing techniques can either be for functional or aesthetic purposes. Each technique has requirements, such as materials, color, texture. High-tolerance CNC milling, turning parts are not recommended to apply secondary metal surface finish, because the treatment may change the sizes of the finished part through removing or adding a small amount of materials. Below are the specifications of the plastic and metal finishing techniques rendered by us.

| Finish | Image | Description | Material | Color | Texture |

|---|---|---|---|---|---|

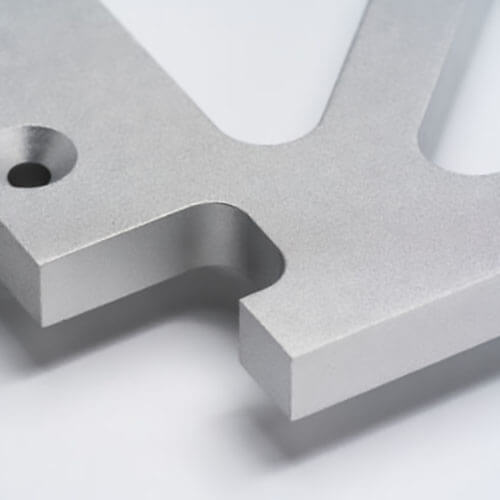

| As-machined |  | The standard finish for our parts, the “as machined” finish, has a surface roughness of 3.2 μm (126 μin), which removes sharp edges and deburs parts cleanly. | All materials | n/a | Stain |

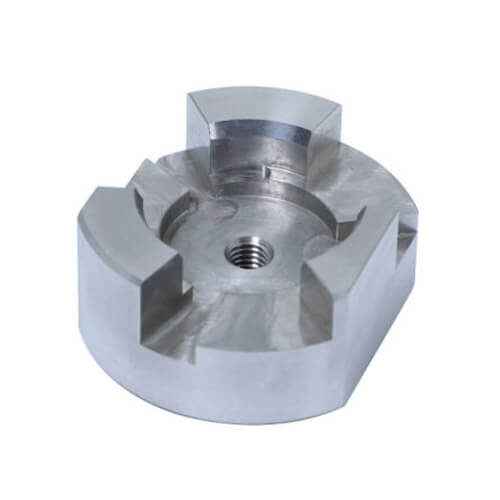

| Abrasive Blasting |  | Abrasive blasting is the process of powerfully propelling, generally with high pressure, a stream of blast media against a surface to remove unwanted coating layers and surface impurities. | Aluminum, Steel, Stainless Steel, Brass, Copper | n/a | Matte |

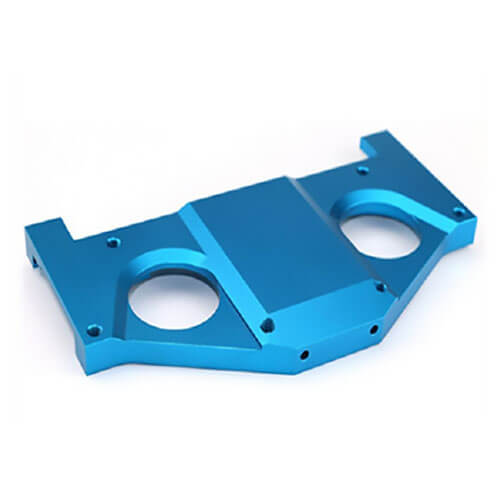

| Anodizing |  | Keeping our parts in the long term, our anodizing process resists corrosion and wear. It’s also an ideal surface treatment for painting and priming, and it looks great too. | Aluminum | Clear, black, grey, red, blue, gold | Smooth, matte |

| Electroplating |  | Electroplated coating preserves the surface of parts and resists rusts and other defects from causing decay by applying electric currents to reduce metal cations. | Aluminum, Alloy Steel, Stainless Steel, Brass, Copper | Gold, silver, nickel | Smooth, glossy |

| Polishing |  | Ranging from Ra 0.8~Ra0.1, polishing processes use an abrasive material to rub the part’s surface to make them shine more less shiny, depending on your requirements. | All materials | n/a | Smooth, glossy |

| Powder Coating |  | Using corona discharge, we make the powder coating adsorbed to the part, creating a more wear-resistant layer with a typical thickness ranging from 50 μm up to 150 μm. | All metal materials | Custom | Glossy |

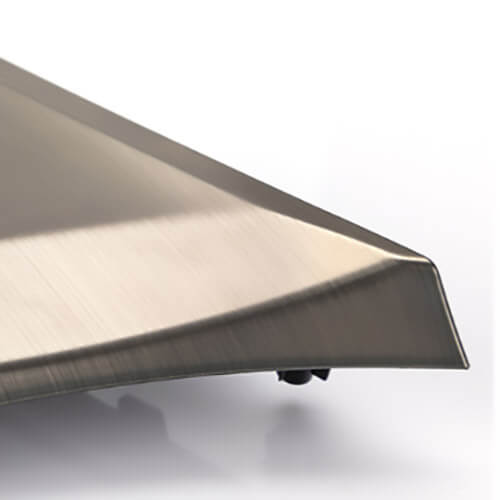

| Brushing |  | Brushing is a surface treatment process in which abrasive belts are used to draw traces on the surface of a material, usually for aesthetic purposes. | ABS, Aluminum, Brass, Stainless Steel, Steel | n/a | Satin |

| Painting |  | Painting involves spraying a layer of paint onto the surface of the part. Colors can be matched to a Pantone color number of the customer’s choosing, while finishes range from matte to gloss to metallic. | Aluminum, Stainless Steel, Alloy Steel | Custom | Gloss, semi-gloss, flat, metallic, textured |

| Black Oxide |  | Black oxide is a conversion coating similar to Alodine that is used for steel and stainless steel. It is used mainly for appearance and for mild corrosion resistance. | Steel, Stainless Steel | Black | Smooth, matte |

| Alodine |  | Chromate conversion coating, known as Alodine, is a chemical coating that passivates and protects aluminum from corrosion. It is also used as a base layer before priming and painting parts. | Aluminum | Custom | Smooth, matte |

Let Seicenc boost your business today!

Seicenc has been in CNC machining industry for 12 years, let us provide you with high quality custom precision machined parts.

By the end of 2022, we have worked with more than 1,000 clients in more than 30 countries, and supplied them over 1 million unique parts.

Do not hesitate. Just contact us right now! We will give you an instant quotaion within one days!