The costs of CNC machining are highly dependent on several factors:

- Machining time

- Cost of material

- Part design and specific requirements, such as finishes and specific tools

- Tolerance allowance

1. Volume of production

Due to its ability to manufacture small and large quantities of parts over a sustained period with minimal supervision when automated, CNC machining represents a cost-effective manufacturing method. However, if only one prototype is required, or a small volume of production, the cost of CNC machining can be increased due to the high initial set-up time.

2. Materials used

Selecting an appropriate material from which your desired part can be manufactured is also an avenue in which cost-saving measures can be implemented. Different materials cost different amounts, and as such, it is crucial that you choose a material that will carry out the desired function of your product, meanwhile not overspending on a material with unnecessary properties. The greater the volume of material required to complete your project, the greater your spending will be. Therefore, parts must be designed to make efficient use of material.

3. Product finish

The smoother the surface finish of a manufactured product, the greater the process required to achieve it, and therefore the greater the cost. As a result, it should be avoided if it is not essential that the manufactured product possesses a high-quality surface finish, such as a low Ra value. Instead, selecting a higher Ra value represents an opportunity to reduce CNC machine costs.

4. No engraving

Due to the detail required to accurately engrave text onto the surface of a manufactured part, excluding additional features such as engraved and/or embossed text is another way to reduce costs. Similar to the principles of the product finish of manufactured parts, if an engraving process is not of critical importance to the manufactured product, it should be excluded from the CNC machining process to lower costs. Often laser etching can be an economical way of adding part numbers or logos.

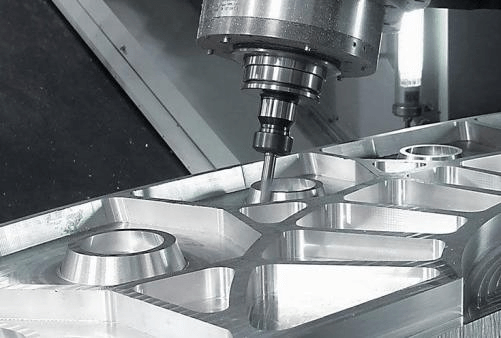

5. Complex geometries are expensive

Parts with geometric complexities come at an increased cost as they often require more expensive multi-axis CNC machinery or manual repositioning of the part.

Let Seicenc boost your business today!

Seicenc has been in CNC machining industry for 12 years, let us provide you with high quality custom precision machined parts.

By the end of 2022, we have worked with more than 1,000 clients in more than 30 countries, and supplied them over 1 million unique parts.

Do not hesitate. Just contact us right now! We will give you an instant quotaion within one days!